When selecting air filtration products for your facility, when utilizing a variable frequency drive system, you should take into consideration 3 important factors.

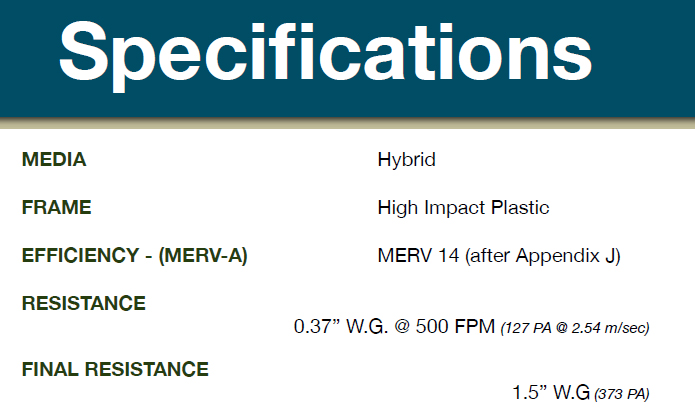

- MERV Value: The MERV rating of an air filtration product identifies a baseline of performance in order to compare one filter class to another. MERV stands for Minimum Efficiency Reporting Value and is the expression of an air filter’s performance when tested in a laboratory using ASHRAE Standard 52.2. The MERV value of a filter can range from MERV 1 to MERV 16.

Generally speaking, the higher the MERV value, the better a filter is at capturing and retaining particulate. Today we look for MERV 8 or MERV 9 rated air filtration products at minimum for HVAC equipment protection. MERV 13 and higher serve for better Indoor Air Quality and Environmental protection. You can normally find the MERV value listed on the product brochure, packaging box, and on the filter itself. For a more indepth look at how MERV testing is conducted, please click here.

Generally speaking, the higher the MERV value, the better a filter is at capturing and retaining particulate. Today we look for MERV 8 or MERV 9 rated air filtration products at minimum for HVAC equipment protection. MERV 13 and higher serve for better Indoor Air Quality and Environmental protection. You can normally find the MERV value listed on the product brochure, packaging box, and on the filter itself. For a more indepth look at how MERV testing is conducted, please click here. - Filter Construction:Air filtration products come in various types of frame materials and filter

media styles. Tradition pre-filtration includes a “Beverage Board” frame that is essentially a moisture repellent cardboard. In many applications we find this style of filter framing material will degrade or fail due to moist environments long before the filter media itself has loaded. We recommend moving to a more rigid frame material, such as plastic or metal, to ensure the filter element will maintain its integrity throughout its service life. Additionally, you should select air filtration products where the filter media pack is fully glued to the framing material. Some manufacturers, in a effort to lower cost, do not glue or seal their filter media to the frame. This creates an opportunity for dirty air bypass around the element. - Resistance To Airflow: When comparing one filter element to another with same MERV rating

and construction, you should select the filter with lowest resistance to air flow throughout its service life. Lower resistance allows an air handler unit to use less energy while still maintaining the rated amount of air flow. Pleated medias allow for low initial resistance, while depth loading filter medias allow for lower resistance throughout the filter’s entire service life. Care should be taken to understand how a particular air filter media, whether surface or depth loading, performs in your application.

and construction, you should select the filter with lowest resistance to air flow throughout its service life. Lower resistance allows an air handler unit to use less energy while still maintaining the rated amount of air flow. Pleated medias allow for low initial resistance, while depth loading filter medias allow for lower resistance throughout the filter’s entire service life. Care should be taken to understand how a particular air filter media, whether surface or depth loading, performs in your application.

No single air filter style should be used in every application. It is important to call on experts, such are Filter Technology Company’s Air Filtration Specialist, to assist you in making the decision on what type of air filtration products should be utilized in your application. We offer complimentary air filter surveys, energy savings calculations, and improvement recommendations that will allow you to operate in the most economical, effective, and efficient manner. Contact us today to learn more.